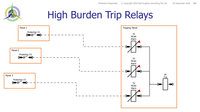

In principle there is no problem associated with direct tripping of a CB by the protection relay contacts - as with all things you simply need to check you have appropriate contact ratings. In the "good old days" there were induction disc type relays where the main operating contact had a limited contact rating or was somewhat delicate so quite often these units had an auxiliary tripping relay included inside to boost the contact rating and endurance. This also had the advantage of giving more than one contact so you could trip the breaker and give an alarm to SCADA. Of course you could put that aux trip relay "anywhere" - inside or outside of the relay box depending on how many terminals you have available. The same is true of numerical relays. In some cases you may need to trip several CBs – e.g. busbar protection so these often have 10 or 20 contacts. The case for an external tripping relay is when there are multiple devices all needing to trip the CB and so you may find it more convenient for operation and maintenance personnel to be able to just deal with isolating one signal associated with the aux trip relay than lots of individuals. These however need to be high-speed trip relays so that overall fault clearance time is not impaired. High speed in some cases requires an “over-powering” of the coil to get a lot of flux happening to operate the armature – so there is a resistor in series with the coil that is initially short circuited and so the coil has a large ‘above rating’ voltage applied to it, and hence a high current pulse to the coil for a short period of 10 ms until the armature operates and opens the shorting contact on the resistor which returns the voltage and current on the coil to its rated values. Because of this high current pulse, we generally call these relays high burden trip relays. The second application of high burden trip relays is when you have multiple trip sources with one trip output relay – e.g. there may be a diff relay, a buchholz relay, a winding temp relay, a …… relay etc. all operating the trip relay. In order to provide flags indicating which caused the trip relay to operate, it was common practice to use a series current operated auxiliary relay (Device 74 shown below such as the MCAA series of relays). Since you wanted to make sure the trip relay (94) and the respective current operated auxiliary (74) to operate, you would use a high burden relay to get enough current flow in the series relay, even accounting for the possibility that perhaps there were two or three series relays that had to flag as if they all operated simultaneously. The availability of all initiation flags on the same Tripping Panel as teh Trip relay therefore makes fault response far more efficient.  Image Added Image Added

Then we have the issue of high burden trip coils on the CB and also the possibility of the CB auxiliary contact failure itself. Most CBs have one f its own auxiliary contact in series with the trip coil so that once the CB has indeed opened as a successful trip, the auxiliary contact cuts off the tripping current and thereby the relay is spared the necessity to break a high value DC current with inductive L/R that would sustain an arc across the open contact. The arc is generated on the relay contact if the CB aux contact has failed, but the CB has opened and the main protection resets, this the trip contact of the trip relay now has to break the trip coil current. This then uses blow-out magnets that sit on the tip of the trip relay contacts that force the arc outwards o increase the arc air distance to extinguish it and this preventing damage to the contacts. But the issue of Lockout is a bit different.

Lockout is about preventing closing of the CB until a potentially permanent fault can be checked and verified by personnel on site as to whether it is safe to close the CB. These Lockouts are generally provided by contacts on the trip relay that have to be manually reset by personnel on site – the contact simply opens circuits the wiring to the close coil of the CB until it is reset. In some cases electrical reset is possible but the operation procedure would normally be that site personnel have to hand reset the unit but ONLY if the personnel have finished their job left site but somehow forgot to reset the relay, then and only then, would the central control room staff be allowed to remotely reset the relay so they could close the CB. So when it comes to Lockout it is a special safety issue. Modern electronic relays sometimes provide a setting which allows the output contact to latch and so can be used as a Lockout. Care must be taken in checking what happens to this Lockout when the auxiliary supply to the relay is removed - will it reset as a volatile output?

What happens when the relay is re-powered up? - will it still be in the Lockout state?

Is there a delay before it "remembers" the output is supposed to be latched in a different position as a Lockout.

Is it necessary/essential the Lockout is retained even though the DC auxiliary to the relay is removed? e.g. working on te panel but teh SCADA system may still have control of the CB close coil. |